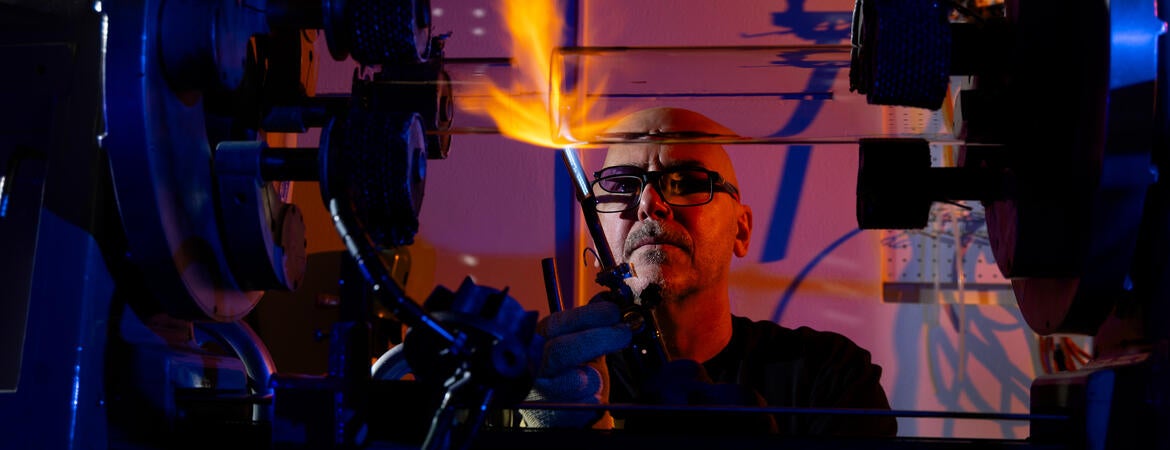

Tucked away next to the Physics Building on the UC Riverside campus is a workshop few people know exists, yet nearly every science department relies on it: the CNAS machine and glass shop. The glass shop, operated solely by scientific glassblower Steven Lepore, quietly supports research across chemistry, physics, biology, and beyond by creating and repairing the custom glassware modern science demands.

“It surprises me how often people say, ‘I had no idea we had a glass shop,’” Lepore said. “But without it, many experiments would grind to a halt.”

Scientific glassblowing is a rare skill; only a handful of UC campuses still have dedicated glassblowers, and Lepore is UCR’s sole expert. He crafts custom scientific apparatus, modifies existing equipment, and repairs costly pieces that labs would otherwise have to replace.

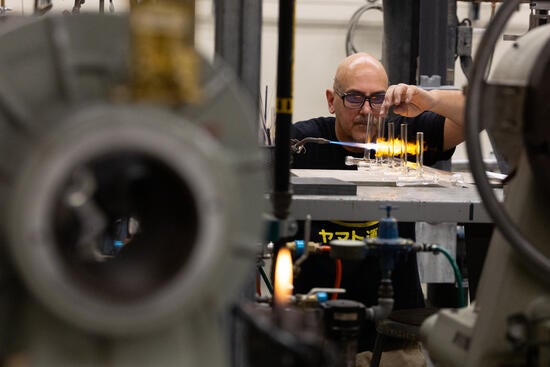

Currently, Lepore is working on a Schlenk line, a common but fragile piece of chemistry equipment.

“Its valves can break easily,” he explained. “A Schlenk line can cost thousands of dollars. Instead of discarding it, I can replace a valve and save the lab a significant amount.”

Lepore’s expertise stems from a three-year scientific glassblowing apprenticeship in Germany around the time the Berlin Wall fell. He then ran his own glass business for nearly 30 years and worked in quartz manufacturing before joining UCR three years ago.

He initially contacted the university “just to see if they needed help.” UCR did, and he started part-time, gradually increasing to two days a week as demand grew.

Unlike commercial manufacturers, university glass shops specialize in unique, one-off creations that no company would mass-produce. Boerge Hemmerling, an associate professor of physics and astronomy, shared an example: a custom quartz vapor cell needed for spectroscopy.

“I contacted a major glass manufacturer,” Hemmerling said. “They told me, ‘We can’t do that. It’s too custom.’ Stephen built it here.”

Another collaboration resulted in an innovative nuclear magnetic resonance (NMR) tube that accommodates a light source — something not available commercially. Lepore and René Riedel, a former postdoctoral researcher at UCR, developed the design, which UCR later patented.

“That was exciting,” Lepore said. “Being part of groundbreaking research and turning ideas into reality is the best part of my job.”

Students often come to Lepore when their research depends on a single broken or custom-made glass part.

“They’ll say, ‘Everything’s stopped. If I don’t get this fixed, my experiment is over.’ We usually turn it around quickly,” Lepore said.

Collaborating with the glass and machine shops also teaches students practical skills. Hemmerling noted that while students arrive with strong theoretical knowledge, they often need guidance on designing within real-world material and fabrication constraints.

“Working with the shop helps them understand what’s physically possible, what tolerances matter, and how to design better,” he said. “It’s an essential part of their training.”

Unlike traditional Italian art glassblowing, scientific glassblowing uses precision tubing heated by torches and shaped with specialized lathes where both ends rotate simultaneously. Lepore blows, stretches, and joins glass with exact control. Finished pieces go into annealing ovens to remove internal stress, ensuring they withstand sudden temperature changes.

The glass shop is equipped with everything from precision glass drills to large lathes for complex assemblies. Half-repaired valves, custom chambers, and intricate tubing line the workspace, showcasing a constant flow of work.

The shop also accepts work from other campuses, including UC San Diego, which currently lacks its own glassblower. Through an intercampus service, labs send their broken or custom glassware to UCR for repair.

Earlier this year, the U.S. Department of Labor recognized Lepore as an expert in his field. UCR’s patented NMR tube design also bears the glass shop’s craftsmanship mark.

“I’m proud of what we do here,” Lepore said. “Whenever I consult outside the university, I make sure UCR gets credit.”

Lepore works closely with machinists Eric Gazelle and Jay Lefler, who handle metalwork, electronics, and vacuum systems. Together, they form a powerful but often overlooked resource on campus.

“We’re an excellent team,” Lepore said. “We solve problems that would stop research anywhere else.”

As more faculty and students discover the shop’s capabilities, Lepore hopes its visibility will grow.

“It’s simple,” he said. “We help keep the science going.”

Header image credit: Stan Lim, UC Riverside.